Unplanned breakdowns and costly repairs often start with poor lubrication. Dynamic Hydraulic Services Company LLC provides dependable lubrication system services in Dover, OH, and nearby areas to keep your hydraulic equipment performing at its best. Our experienced team supplies quality lubrication components, installs complete grease and oil systems, and maintains both mobile and industrial setups. Each piece of equipment has unique lubrication needs, so we deliver solutions tailored to your operations. This helps you avoid unnecessary wear and improves reliability.

Contact us to upgrade your equipment’s lubrication and protection!

Comprehensive Lubrication System Sales and Installation

We offer a wide range of lubrication components, such as pumps, fittings, hoses, injectors, reservoirs, and control panels from manufacturers you trust. If you need to upgrade a machine or install a new system, our technicians provide full sales support and professional installation. We work with both grease and oil lubricant systems, making sure your equipment receives the right solution for its application.

Grease and Oil Lubricant Systems for All Industries

Different equipment and environments require different types of lubrication. We serve industrial machines with complex lubrication needs. From small single-point systems to large automated setups, our team can recommend, install, and service grease and oil solutions for heavy-duty performance.

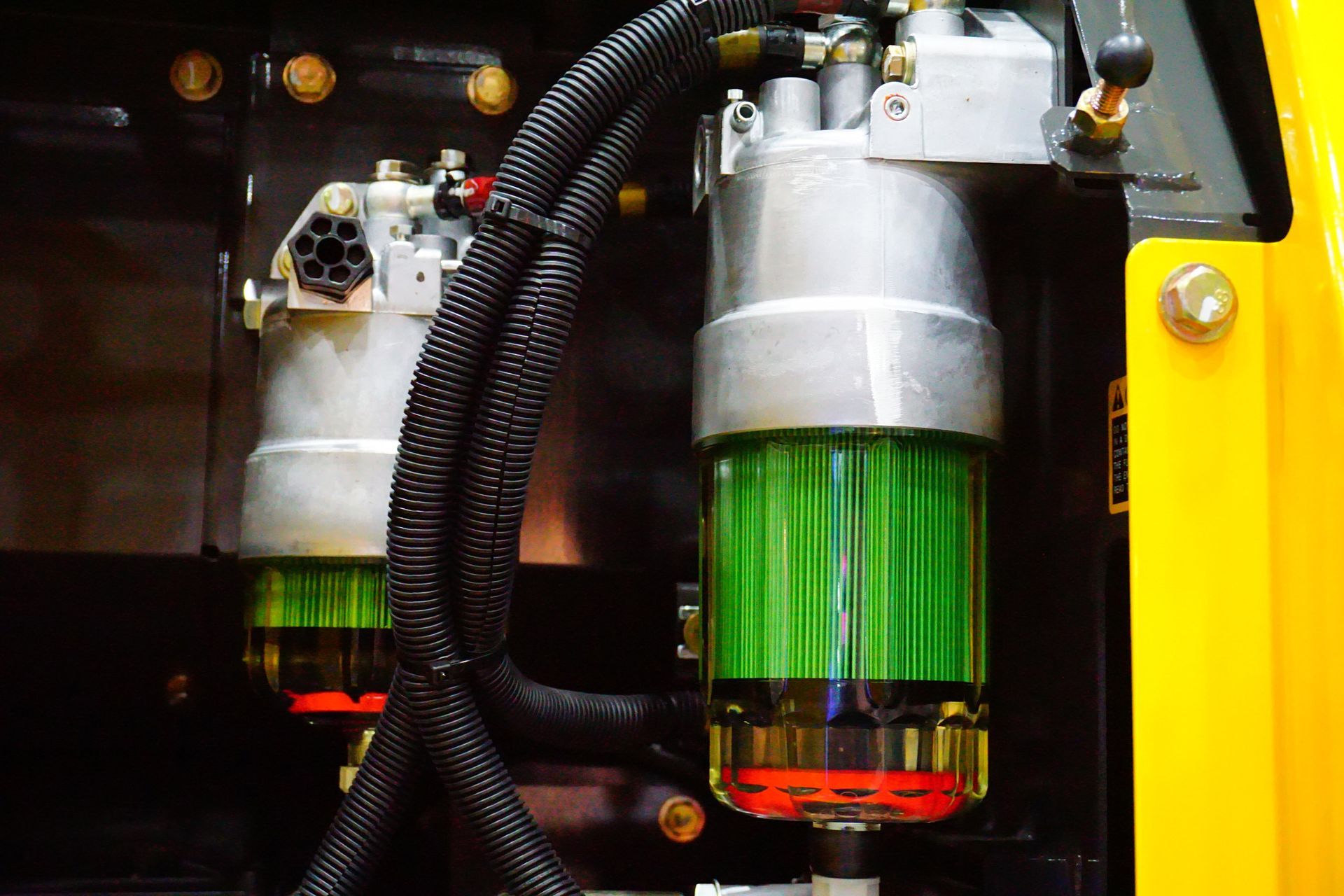

Oil Filtration, Dehydration, and Maintenance Services

Clean oil is essential for proper lubrication and long equipment life. Dynamic Hydraulic Services Company LLC provides thorough oil filtration and maintenance for hydraulic systems. We inspect filters, replace elements, monitor oil quality, and perform regular fluid changes. Keeping oil clean and free of contaminants helps you extend the life of your equipment and prevents unexpected breakdowns.

Customized Lubrication Solutions for Your Equipment

Each operation is unique, and we take the time to understand yours. Our technicians will design and install lubrication systems configured for your specific machinery, worksite, and production schedule. We offer detailed recommendations, clear installation plans, and support for ongoing lubrication management.

Mobile and Industrial Equipment Expertise

We bring specialized knowledge and hands-on experience to both mobile and industrial lubrication systems. Our team understands that each type of equipment faces unique challenges, and a one-size-fits-all solution doesn’t work when it comes to proper lubrication.

Mobile Equipment Solutions

Mobile machinery, such as trucks, construction vehicles, agricultural machines, and service fleets, often operates in tough conditions. Dirt, vibration, and constant movement make consistent lubrication vital for reliable performance. We install and maintain lubrication systems that automatically dispense grease or oil while equipment is in use, helping critical parts stay protected and reducing time spent on manual maintenance. Our mobile solutions are designed for durability and easy upkeep, no matter where your equipment goes.

Industrial Equipment Systems

In factories, plants, and other industrial environments, hydraulic systems power presses, conveyor belts, production lines, and more. These machines usually run for long hours and need steady, precise lubricant delivery to avoid breakdowns and costly downtime. We design, install, and service centralized and automated lubrication systems tailored to each machine’s specific requirements. Our team ensures that every moving part receives the right amount of lubricant, helping you maintain efficiency and extend equipment life.

Preventive Maintenance Programs

Keeping your hydraulic equipment reliable starts with proper care for its lubrication systems. We offer tailored preventative maintenance programs for businesses in Dover, OH, and surrounding areas. These programs are designed to catch minor issues before they become major problems, saving you time, money, and headaches down the road.

Routine Inspections and Service

Our technicians schedule regular visits to inspect your grease and oil lubrication systems. During each inspection, we check for leaks, worn parts, blocked lines, and any signs of contamination. We also verify that lubricants are being delivered at the correct intervals and in the right amounts for every piece of equipment.

Filter and Component Replacement

Filters and other lubrication components need regular replacement to keep systems working efficiently. Our team tracks service intervals, replaces filters and worn parts, and ensures your machines are protected from harmful debris and wear.

Lubricant Management

We monitor lubricant levels and quality, performing oil or grease analysis to detect early signs of contamination or breakdown. If fluid changes are needed, we handle them promptly to prevent damage and maintain optimal system performance.

Customized Maintenance Plans

Every operation is different. We work with you to develop a schedule that suits your equipment, workload, and budget. Whether you have just a few mobile units or a full-scale industrial facility, our maintenance programs are flexible and easy to manage.

Reporting and Communication

At each visit, we provide clear reports detailing our findings, actions taken, and recommendations for any additional work. You always know the condition of your lubrication systems and can plan for future needs.

Request your free lubrication system estimate today!